Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Experimental Study on the Treatment of Rising Dampness and Evaluation of Compressive Strength and Efflorescence in Various Bricks Types

Authors: Billa Gnana Prasanna Devi, Kacharla Sunil Kumar R

DOI Link: https://doi.org/10.22214/ijraset.2025.66543

Certificate: View Certificate

Abstract

One of the most serious factors contributing to the degradation of both old and new construction is rising damp. This phenomenon, which is well-known worldwide, happens when groundwater rises and flows through porous masonry materials. The installation of damp-proof courses (DPCs) has been the focus of remedial therapies for several years now, since studies worldwide have determined that the degradation at the base of walls is solely attributable to the phenomena of rising damp. But in nations with hotter, drier climates and more salinized soils, water evaporates from walls at higher rates, which causes soluble salts to build up in the masonry\'s evaporation zone. The humidity levels and the formation of mould pose health risks to the inhabitants of the building. Extensive fretting and cracking of the lowest portions of walls might result from severe rising damp and excessive salt concentrations. The issue of growing humidity has been addressed in several ways, but removing it from both contemporary and old structures is still quite difficult. The experimental study was conducted on several different types of bricks. The study utilised fly ash cement bricks, polypropylene (PP), polyethylene terephthalate (PET), modular class A-1 bricks, and a blend of plastic and fibre bricks. The partition wall supports horizontal beams, and since concrete is weak under stress, adding fibres in the right amount to bricks helps control growing dampness and fractures. The wall may also withstand rising moisture by applying damp-proof coatings. We examined the mechanical properties of brick construction, including compressive, water-absorption, effloresces, and dimension and tolerance tests. In this research, 75% of the fibres have an aspect ratio, while 85% are plastic fibers. Fibres\' contribution to brick building and propagation is most evident after matrix mixing, which enhances the walls\' appearance, texture, strength, hardness, durability, porosity, absorption, and fire resistance. The inclusion of bricks, polypropylene granules, plastic granules, and plastic flakes gives the wall more strength, stops the wall\'s capillaries from absorbing moisture, and lessens internal wall degradation, water absorption, leaks, and spalling. Chemically fibred bricks, added at 7, 14, and 28 days of mechanical testing, increase the compressive strength of fibre-reinforced plastic bricks compared to modular bricks. We calculate the results of these tests to enhance the compressive strength, reduce efflorescence, and enhance the dimensions and water absorption.

Introduction

I. INTRODUCTIONS

Dampness is the presence of unwanted moisture in the building structure it is either the result of intrusion from condensation from within the structure. A high proportion of damp problems in buildings are caused by the surrounding climate-dependent factors of condensation and rain penetration. The Dampness problem has been a concern since ancient times especially the rising damps which are caused because of the water above the ground level Roman architect and engineer Vitruvius referred to the problem of dampness rising walls and advised on how to construct buildings to avoid the problem. Dampness in the building leads to weakening in the strength of the materials and can cause the structure to fail and damage the property as well, it also creates an unhealthy environment for the users Damp in the building occurs mostly on the floors and the walls of the building because the floors are close to the ground and the walls are directly exposed to the outside weather.

Dampness in the wall ruins the paint and also the decorations and quality of the wall, it can result in the rotting of timber, especially timber fitting doors and windows therefore prevention and treatment of dampness in the building are necessary to find the sources of the moisture is important since moisture is the main cause of the dampness.

The proposed treatments if adopted could control the problem of rising dampness, especially in the construction of new buildings. when porous masonry draws up water from the ground. The water rises the wall, about a meter or higher, and often deposits a horizontal ‘tide mark’.

Below this mark, there is discoloration of the wall that is characterized by a general darkening, patchiness, and mold growth. The amount of water absorbed by the wall, and the height to which it rises depend on the ability of the masonry to absorb moisture the level of wetness of the soil, and the rate of evaporation of the moisture. Agyekum at. el [1].In this research, discussed the content of water-soluble salts and the degree of wetting. It describes the interventions against the moister. Three types of salts are commonly analyzed in masonry, which is the most common cause of the destruction of masonry and plaster - sulfates, chlorides, and nitrates. Some of the sulfates get into the masonry from the soil. The increased content of these salts increases the humidity of the attacked structure of the building. The salts make the attacked structures capable of binding to water. molecules, so they become hygroscopic and also change the capillary properties of the building materials and reduce the natural evaporation of water from the masonry surface as it clogs the pores on its surface. Determination of the degree of wetting of the structure, determination of the amount of water-soluble salts. Patrik Jozef, Oto[2].In this research, they have observed that salt damage can affect the service life of numerous building structures, and various damage mechanisms to porous building materials induced by salt action are analyzed.

Here, The salt damage treatment is assessed, including both passive techniques based on environmental control, reduction of water transport, or conversion to less soluble salts and active procedures resulting in the removal of salts from deterioration zones. Severe considering the presence of salts in water. The treatment of rising dampness in historic building walls is a very complex procedure. Laboratory of Building Physics (LFC-FEUP) a wall base hydro regulated ventilation system was developed and patented. S.Guimaraes [3]. The studies on the bond strength of brick masonry under flexural, tensile, and shear loading are discussed. The bond strength of clay brick and soil cement block masonry is studied while fly ash brick masonry has not got the attention. It is reported that the brick mortar shear bond strength is dependent on various factors such as surface characteristics of bricks, property of mortar, etc.

Mercedes Del Rio Merino et al [4] In this research, have observed the presence of moisture in traditional bricks placed inside decreases their thermal and mechanical performances the variability of these properties as a function of saturation is essential to the material over time, and to characterize the durability of the restoration of the new materials. The laboratory survey campaigns the medium Compressive strength of these materials in saturated and semi saturated Conditions can experience a reduction of up to 40% on

specimens tested in dry conditions. It affects the mechanical strength the filling of capillary pores with water alters the physical characteristics they showed that the presence of water produces an increase in weight and volume of the material which varies depending on its mineralogy. Withaya Panpa.[6] This research aims at producing high-strength, water- resistant, gypsum-based materials (from used plaster molds) with the additions of glass cullet and types of cement and investigating the influence of glass cullet contents on their properties. Block-shaped specimens of gypsum mortars. containing 70–90 wt% β- β- hemihydrate with up to 20 wt % cullet waste powder and a small amount of Portland and calcium aluminate types of cement, as early strength enhancer and setting time modifier, were cured under damp, ambient air for 7–28 days. Properties includingsetting times, water absorption, compressive strength, water resistance, volume change, and microstructure were observed. Ahed and F. Abdul Rahman et al.[7] According to them, the problems of rising dampness and salt attack are closely related since moisture from rising dampness can dissolve existing salts in a building material. Groundwater may sometimes contain salt and can find its way through the walls of a building by capillary action. Thomas Worthington at el.[8] described rising dampness in his essay and recommended that a damp proof course (DPC) should be used to disconnect the whole of the foundations from the superstructure. Rising dampness was reported to occur if the moisture content of mortar samples was above 5% and it was found that 54% of the properties suffered from rising dampness at heights of 0.3m above the floor level.

II. MATERIALS PROPERTIES

A. Collection of Materials

Brick is one of the primary materials used in this study. Three variants of brick are considered, out of which one is clay brick and the other two are fly ash bricks. Burnt clay bricks used in the present study are procured from a kiln. The clay bricks used are of good quality and fall under the class designation of 7.5 as per Indian Standard IS 1077:1992 classification.

The cement was Ordinary Portland cement of 53 grade, Confirming code 12269-2013. The Chemical Properties of Common Portland Cement have been studied in the following IS 12269. The physical properties of cement have been looked at based on IS 4031. The physical and mechanical properties of both fine and coarse aggregate have been tested by IS 2386.

The strength of the brick-mortar joint under shear force is determined by testing masonry triplets under direct shear loading. In this study, the masonry triplet specimens are constructed as specified in an earlier section. The specimen is placed in a compression testing machine or universal testing machine where loading is applied through a plunger.

Two support blocks are provided under the two end bricks and loading is applied on the centre brick. The load at which the middle brick detaches from masonry is the failure load. The strength is calculated by dividing the load by twice the surface area of the brick. Fig. 1 shows the test setup of the shear bond strength test with the triplet specimen.

Figure 1: Compressive strength test of Brick and Water Absorption Diagonal shear failure

Figure 2: Vertical splitting failure in (a) CB (b) FAB-I and (c) FAB-II prisms

Crushing failure Figure 2 Crushing failure in (a) CB (b) FAB-I and (c) FAB-II prisms Low- strength bricks fail through this mode early without utilizing the full strength of brick-mortar bond resulting in a lower masonry strength. the chapter presents the morphology and microstructure of brick specimens based on Chemical Analysis results showing that the presence of silica, aluminum, calcium, and oxides of iron and magnesium are important.

B. Interpretation of Chemical Analysis.

Chemical analysis is conducted for the brick units of all six variants and mortar specimens of three mortar grades. The samples are selected from the brick specimens which showed maximum and minimum compressive strength among the range of specimens tested. This analysis is useful in understanding the unknown chemical compounds present in a material. The procedure is explained in Section 3.4.2.1 of Chapter 3. The chemical properties responsible for differences in compressive strength of brick specimens are studied from the analysis. It is observed that the absence or presence of some chemical compounds affects the strength of brick greatly. A similar analysis is also conducted on representative specimens of three grades of mortar.

Figure 3: Comparison in Chemical Process of Bricks

C. Chemical Analysis of Brick Units

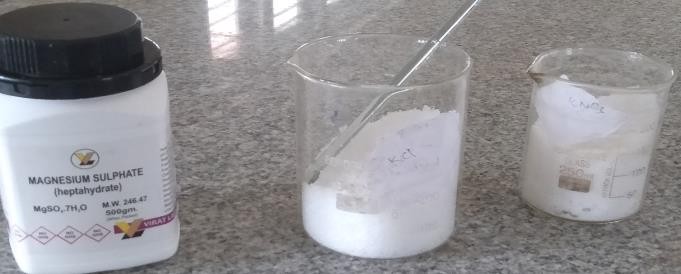

It is known that good bricks should have a composition that includes chemical compounds of silica, potassium, alumina, lime (calcium), oxides of iron, and magnesium The presence of such compounds is verified from Chemical patterns.

Figure 4: Chemicals of Magnesium, Potassium Chloride, Sodium chloride

Figure 5: Mix Ratio of 1: 3 & 1:4 motor Cubes

D. Sulphate Attack in Bricks

Brick sulfate attack is a major cause of concern for its long-term serviceability and durability. Due to the assault's complexity, a wide range of theories about how it operates have been produced, some of which are completely at odds with one another. Gypsum develops predominantly due to the first form of sulfate assault, while gypsum is primarily produced due to the second type of sulfate attack. The second product that results from the interaction of gypsum with tricalcium sulfate aluminate is ettringite.

Figure 6: Sulphate Attack of Brick

E. Acidic type of Sulfate Attack

It is characterized by the cement matrix being eaten away or softened, leaving the particles protruding from the eroded concrete. This type develops because of the development of gypsum and low-C3A cement.

F. Chloride Attack in Bricks

One of the most important elements impacting the durability of concrete is the attack of chloride. It mostly damages and corrodes concrete reinforcing bars. There are several choices to think about when adding chlorides to control during or after construction.

Figure 7: Chloride Attack of Bricks

III. EXPERIMENTAL RESULTS & DISCUSSIONS

The following physical properties of OPC cement, aggregates of fine and coarse aggregates are followed as per the code (IS- 12269-1987).

A. Physical Properties

Table 1: Physical Properties of Ordinary Portland Cement (OPC 53 Grade)

|

S. No |

Property |

Test Method |

Test Results |

|

1 |

Normal consistency |

Vicat apparatus (IS 4031-Part 4) |

33% |

|

2 |

Specific gravity |

Specific gravity bottle (IS 4031-Part 11) |

3.15 |

|

3 |

Initial setting time |

Vicat apparatus (IS 4031-Part 5) |

50 min |

|

4 |

Fineness |

Sieve test on 90-micron sieve (IS 4031-Part 4) |

9% |

Table 2: Fine Aggregate fineness modulus ranges

|

Type of sand |

Fineness modulus range |

|

Fine sand |

2.2-2.6 |

|

Medium sand |

2.6-2.9 |

|

Coarse sand |

2.9-3.2 |

Table 3: Properties of Fine Aggregate and Coarse Aggregate

|

Sl. No. |

Property |

Test Method |

Test Results for Fine Aggregate |

Test Results for Coarse Aggregate |

|

1 |

Specific gravity |

Pycnometer (IS 2386-1986 Part-3) |

2.65 |

2.74 |

|

2 |

Bulk density

|

(IS 2386-1986 Part 3) |

1635 Kg/m3 1766 Kg/m3 |

1450 Kg/m3 1571Kg/m3 |

|

3 |

Fineness modulus |

Sieve analysis (IS 2386-1963 Part 2) |

2.90 |

7.16 |

As the following properties in specific gravity by using pycnometer the results are for fine aggregate is 2.65, for coarse aggregate is 2.74. As the bulk density for loose, and compacted is 1450 kn/mm2, 1571 kg/mm2, and fine ness modulus of sieve analysis for fine aggregates is 2.90 and 7.16.

Table 4: Physical Properties of Polyethene terephthalate.

|

S.no |

Properties |

Results |

|||

|

1 |

Technical name |

Polyethylene terephthalate |

|||

|

2 |

Chemical formula |

(C 10 H6 O11) n |

|||

|

3 |

Melt Temperature |

260 ?C |

|||

|

4 |

Typical Injection |

74-91? C |

|

||

|

5 |

Heat deflection |

70 ? C |

|

||

|

6 |

Tensile strength |

152 MPa |

|

||

|

7 |

Flexural Strength |

22 MPa |

|

||

|

8 |

Specific Gravity |

1.56 |

|

||

|

9 |

Shrink rate |

0.1-0.3% |

|

||

Figure 8: Sample of High-Density Polymers

B. Mechanical Properties

The following Experimental Results and Discussions discuss the mechanical Properties are water Absorption, Compressive Strength, and Bulk Density, Efflorescence.

1) Water Absorption

Table 5: Water Absorption by Different Types of Bricks

|

S.No |

Type of Brick |

Water Absorption (ml) |

|

1 |

Polyethylene terephthalate (PET) |

1.03 |

|

2 |

Low density polyethylene (LDPE) |

0.93 |

|

3 |

Fly ash Bricks |

6.97 |

Table 5 is the result of water absorption by different types of Bricks. The following types of Bricks as the Modular Clay Bricks have acquired the Highest water Absorption than the fly ash Bricks. By comparing the LDPE and Polyethylene Terephthalate (PET) has acquired a Water Absorption of 1.03% of water absorption than the Lowest water Absorption of LDPE is 0.93%.

2) Compressive Strength of Concrete

Table 6: Compressive Strength of Various types of Bricks

|

S. No |

Polyethylene terephthalate(pet)(KN) |

Polypropene) (KN) |

Fly ash cement Bricks (KN) |

Conventional bricks (KN) |

|

1 |

180 |

320 |

230 |

30 |

|

2 |

175 |

315 |

210 |

25 |

|

3 |

190 |

300 |

250 |

28 |

|

4 |

120 |

330 |

220 |

30 |

|

5 |

185 |

320 |

230 |

27 |

Table 6: Calculation of surface area and Compressive strength of various Types of bricks.

|

Sl.no |

Name of the Sample blocks |

Dimension of Bricks (mm) |

Area of surface (mm2) |

Maximum Load (KN) |

Compressive strength (N/mm2) = max load / Area |

|

1 |

Modular Clay Bricks of the sun-dried |

225x100x80 |

22500 |

335 |

14.88888889 |

|

2 |

High-density Polymers blocks (blue) |

225x95x75 |

21375 |

440 |

20.58479532 |

|

3 |

Polyethylene terephthalate (Green Granules) |

228x98x80 |

22344 |

195 |

8.727175081 |

|

4 |

Polypropylene Flakes |

230x98x80 |

22540 |

315 |

13.97515528 |

|

5 |

Fly Ash Bricks |

230x100x80 |

23000 |

210 |

9.130434783 |

|

6 |

Low-Density Polymer Bricks |

201x100x95 |

20100 |

185 |

9.2039801 |

The mean compressive strength of the commercially manufactured High-density polyethylene block at 28 days’ age of 18.53N/mm2 fell far below the minimum compressive strength of 8.174N/mm2 recommended for the load-bearing wall. The results in Table 6 show that the standard manufactured Low-Density poly ethylene blocks had lower Compressive strength capacities than the Manufactured Modular clay blocks. This means that although all two sets of blocks can resist water, standard manufactured Low-Density polyethylene blocks are more durable and can withstand the elements of the weather with normal protection.

|

Compressive test of wall with DPC 450 400 350 200 300 150 |

|

Maximum Load (KN) |

|

100 |

|

Compressive strength (N/mm2) = max load / |

Figure 9: Compressive strength of various Types of bricks.

As the Modular Clay Brick has a compressive strength of 280N/mm2, polyethylene bricks (green flakes) accrued 150N/mm2, and polypropylene flakes bricks red over 250 N/mm2.as compared to fly ash bricks which have 150 N/mm2 and auto-claved Aerated Bricks which have 135 N/mm2.As compared to all of these compressive test results ,High Density Polymers have the highest compressive strength of 425 N/mm2 over the results of 28 days period of time.

C. Variation in Bulk Density

Bulk densities were obtained for the standard and commercially manufactured High-density polypropylene blocks. The results showed that significant differences existed between the bulk densities of the standard manufactured blocks and the commercially manufactured Polypropylene blocks. The average bulk densities of the standard manufactured Polypropylene blocks exceeded the commercially manufactured High-Density Polypropylene blocks by 16.5% and the BS recommended minimum bulk density (IS 2185 PART 1:2005) of 204 kg/m3 by 53.47%. The average bulk densities of standard and commercially manufactured Polypropylene blocks also exceeded the BS recommended bulk density of 1500kg/m3 (IS 2185 PART 1:2005). The results show that both the standard and commercially manufactured Polypropylene blocks used in this study were sufficiently compacted.

1) Efflorescence

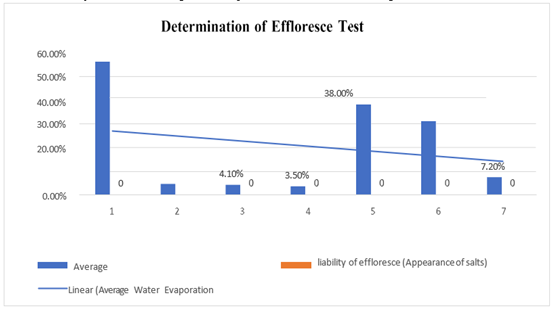

Table 7: Determination of Efflorescence

|

S. No |

Type of Bricks |

Average Water Evaporation |

Liability of Efflorescence (Appearance of salts) |

limit range |

Liability of Effloresce |

|

1 |

Modular Clay Bricks |

56.00% |

heavy |

0% |

nil |

|

2 |

High Density Polyethylene Bricks |

4.40% |

slight |

0-10% |

slight |

|

3 |

Polyethylene Terephthalate Bricks |

4.10% |

slight |

10-30% |

moderate |

|

4 |

Low-Density Polyethylene brick |

35.0% |

slight |

30-50% |

slight |

|

5 |

Fly Ash bricks |

38.00% |

Moderate |

50-60% |

moderate |

|

6 |

Leight-weight aerated Bricks |

31.00% |

Moderate |

50-70% |

heavy |

|

7 |

Aerated Bricks |

72.0% |

slight |

70-100% |

serious |

Figure 10: Determination of Efflorescence

The Modular Clay Brick has an average water evaporation of 56% of the limit range as to compared to aerated bricks water evaporates 72% which causes serious action to bricks and structures. Compared to high-density polyethylene bricks cause low efflorescence, polyethylene Bricks has got the salts 35% slight liability of effloresce, and fly ash bricks have accrued moderate condition of effloresces.

D. Optimum Moisture Content

The optimum moisture content of bricks for which higher shear bond strength is achieved based on the experimental results is discussed in this section. The variation of shear bond strength with an increase in moisture content of CB triplets is shown in Fig. 5.7 for various mortar grades. The shear bond strength is found to be higher for triplets made with mortar having a higher amount of cement.

The bond strength plot follows a rising trend up to the third point after which it starts decreasing. There are four points in the plot signifying each of four sets of triplet specimens A, B, C, and D. The strength is 0.082 MPa for CM1, 0.097 MPa for CM2, and 0.127 MPa for CM3 grade mortar when the moisture content of brick is 4.16% or 25% of its saturated moisture content (Set-A).

Figure 11: Comparison of bricks without DPC and with DPC and Different Types of Brick Walls

Conclusion

The following are the conclusions drawn from the present investigations 1) To describe the variability in the mechanical properties of clay and fly ash brick masonry 2) To model the compressive strength of brick units and brick masonry 3) To determine the optimum pre-wetting of bricks to have higher shear bond strength of brick masonry. 4) The review of kinds of literature paved the path to identifying the voids in past studies related to brick masonry. All the kinds of literature that benefitted this research work are explained in Chapter 2 of this thesis under various sections. 5) Several experimental tests are conducted on specimens of brick masonry and its constituents to determine properties such as initial rate of absorption (IRA), water absorption (WA), dry density, compressive strength, and shear bond strength are also conducted to understand the morphology and microstructure of brick specimens. 6) Three brick variants (CB, FAB-I, and FAB-II) and three mortar grades (CM1, CM2, and CM3) are used in the present study for the preparation of test specimens. The experimental plan, details of raw materials used, preparation of test specimens, equipment used, and procedures of experimental work carried out are explained in Chapter 3. 7) Variability in the properties of brick masonry using various Chemical Analyses. Four different two-parameters of HCL, H2SO4, KCL. This chapter also identifies the influence of morphology and microstructure on the properties of bricks. A relation between the mechanical properties is established and equations are proposed to predict the compressive strength of brick and brick masonry. The failure patterns of masonry prism under axial compression observed in the study are discussed. 8) The results and discussions where experimental work was carried out. variation in moisture content in bricks is achieved by soaking them in water for the required time. The test is performed on triplets constructed with different typesof bricks (CB, FAB-I, and FAB-II) and mortar grades (CM1, CM2, and CM3). A. Scope for Future Work The present study can be extended to include the variability of the deformation and ductility properties of brick units and brick masonry. This study will help to establish a statistically significant model for the nonlinear stress-strain behavior of fly ash bricks.

References

[1] Agyekum, K., Ayaka, J., & Koranteng, C. (2016). Controlling rising damp in new buildings: field trials of proposed treatment methods. In Proceedings of International Conference on Infrastructure Development in Africa, Johannesburg (pp. 447-466). [2] Š?astný, P., Gašparí, J., & Makýš, O. (2021). Analysis of moisture and salinity of historical constructions before and after the application of remediations. Journal of Building Engineering, 41, 102785. [3] Delgado, J. M. P. Q., Guimarães, A. S., De Freitas, V. P., Antepara, I., Ko?í, V., & ?erný,R.(2016). Salt damage and rising damp treatment in building structures. Advances in Materials Science and Engineering, 2016. [4] Vitiello, V., Castelluccio, R., & Merino, M. D. R. (2020). Experimental research to evaluate the percentage change of thermal and mechanical performances of bricks in historical buildings due to moisture. Construction and Building Materials, 244, 118107. [5] Franzoni, E., Rirsch, E., & Paselli, Y. (2020). Which methods are suitable to assess the effectiveness of chemical injection treatments in the laboratory? Journal of Building Engineering, 29, 101131. [6] Buggakupta, W., Tounchuen, K., Panpa, W., & Jinawath, S. (2020). Early production of high strength and improved water resistance gypsum mortars from used plaster mold and cullet waste. Journal of Materials in Civil Engineering, 32(6), 04020116. [7] Agliata, R., Mollo, L., & Greco, R. (2017). Use of TDR to compare rising dampness in three tuff walls made with different mortars. Journal of Materials in Civil Engineering, 29(4), 04016262. [8] T Abbott, AJ Fowler, P Pelosi, et al(2016). The water absorption capacity of the masonry, the salts crystallize out on the wall surfaces, often concentrating. Journal of Materials in Civil Engineering, 30(5). [9] R. Burkinshaw et al.[9] Controlling rising damp in new buildings: field trials of proposed treatment methods. In Proceedings of International Conference on Infrastructure Development in Africa, Johannesburg (pp. 589 -610). [10] Thomas Worthington at el. [10]. (2021). Analysis of moisture and salinity of historical constructions before and after the application of remediations. Journal of Building Engineering, 41, 102785. [11] IS 3952 (1988): burnt clay hollow bricks for walls and partitions - Specification [CED 30:Clay and Stabilized Soil Products for Construction [12] IS 13757 (1993): Burnt clay fly ash building bricks-Specification [CED 30: Clay and Stabilized Soil Products for Construction] [13] IS 13182 (1991): Waterproofing and Damp-Proofing of Wet Areas in Building -Recommendations [CED 41: Waterproofing and Damp-Proofing [14] IS 3067 (1988): Code of practice for general design details and preparatory work fordamp-proofing and water-proofing of buildings [CED 41: Waterproofing and Damp-Proofing. [15] Standard code is used for the burnt clay brick performances, Maintenance: IS 3495( part 3): 1992 And IS 2185(part 1): 2005.

Copyright

Copyright © 2025 Billa Gnana Prasanna Devi, Kacharla Sunil Kumar R. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET66543

Publish Date : 2025-01-16

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online